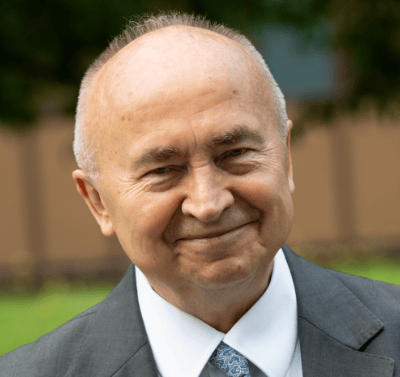

Jan Taler

Jan Taler

Department of Energy, Cracow University of Technology

jan.taler@pk.edu.pl

A new method for flow-thermal and strength calculations of supercritical steam superheaters

BIO

Professor Jan Taler is a Full Professor at the Cracow University of Technology, currently serving as the Director of the Department of Energy in the Faculty of Environmental and Power Engineering, a role he has held for 33 years.

Prof. Taler's educational background includes a Master of Science in Mechanical Engineering from the Cracow University of Technology (CUT) in 1974, followed by a Ph.D. in 1977 and a D.Sc. in 1987, both in Mechanical Engineering from CUT. He was awarded the title of Professor in 1994 and became a full professor in 1996. He also received scholarships from the DAAD and the Alexander von Humboldt Foundation to study at Universität Stuttgart during the early 1980s.

He has contributed extensively to his field, authoring or co-authoring 450 journal and conference papers, 12 books, and 26 book chapters. Prof. Taler was the editor of the "Heat Conduction – Direct, Inverse and Optimization" section in the 2014 Springer Encyclopedia of Thermal Stresses. He also serves on the editorial boards of the Journal of Thermal Stresses and the Journal of Thermal Science. His contributions to scientific research are validated by an impressive number of over 3000 citations with an h-index of 29.

Prof. Taler’s research focuses on heat transfer engineering and thermal power engineering, particularly in areas such as inverse heat conduction problems, measurement of heat flux and heat transfer coefficients, heat exchangers, ash fouling and slagging in steam boilers, the dynamics of large steam boilers, numerical modelling of superheaters, thermal stresses, structural analysis using Finite Element Analysis (FEM), and the monitoring and lifespan prediction of power boilers. Notable scientific contributions include:

- Developing several numerical methods for solving inverse heat conduction problems, particularly the space marching method for monitoring thermal stresses in pressure components.

- Creating analytical and numerical methods as well as instruments for measuring heat flux and heat transfer coefficients.

- Developing mathematical models for simulating steam boiler operations.

- Establishing a computer-based system for online monitoring of thermal stresses and predicting the remaining lifespan of pressure components in steam boilers.

- Developing a computer system to monitor ash fouling and slagging in coal-fired utility boilers.

Prof. Taler has held significant positions in scientific and professional organizations, including:

- Member of the Council of Polish Science (2005-2008).

- Vice-chairman of the Thermodynamics and Combustion Committee of the Polish Academy of Sciences (2008-2010).

- Member of the Thermodynamics and Combustion Committee and the Committee of Energy Problems of the Polish Academy of Sciences (since 2002).

- Member of the Polish Association for Theoretical and Applied Mechanics (since 1983).

- Member of the Association of Polish Mechanical Engineers (since 1977).

- Member of The Central Commission for Academic Degrees and Titles in Poland (since 2012).

- Vice-president of the Association for Education of Specialists in Construction of Power Plant Machinery (since 2003).

- Member of the Scientific Council of the International Centre for Heat and Mass Transfer (since 2018).

- Member of the Polish Academy of Sciences (since 2020).

Prof. Taler has received numerous accolades for his contributions to science and education, including the Siemens Prize for Research Achievements in 1996, the Gold Badge of the Cracow University of Technology in 1993, and the Service Gold Medal in 1993, along with a distinction for his service to the Cracow University of Technology in 2007.

ABSTRACT

J. Taler, K. Węglarz, D. Taler, M. Marcinkowski

An analytical-numerical method for modelling high-temperature tube cross-flow heat exchangers is proposed. The entire heat exchanger is divided into finite volumes. The momentum and energy conservation equations were solved analytically in a single finite volume region, considering the dependence of the fluid's specific heat on pressure and temperature.

Steam pressure changes along the path of its flow in the tubes were determined by numerically solving the momentum conservation equation. The heat transfer coefficient at the outer surface of the tubes is calculated taking into account heat transfer by forced convection and radiation. A layer of ash or other deposits on the outer surface of the tubes is also included.

The method is explicit and does not require solving a nonlinear system of algebraic equations to determine the temperature at the nodes of the finite volume. The developed method is suitable for calculating tubular heat exchangers operating at sub- and supercritical pressures, especially for supercritical steam superheaters in large steam boilers. The number of finite volumes along the length of one pass of the heat exchanger can be small since exact analytical formulas are used to determine the temperature distribution of steam and flue gas inside the finite volume.

A new formula for calculating the friction factor in tubes with a rough inner surface was proposed. Equations for calculating the Reynolds number limit above, for which the friction factor depends only on the relative roughness of the tube surface, were determined.

The results of calculations of steam, flue gas, tube wall temperatures and steam pressure in the final stage of the live steam superheater installed in a 900 MWe boiler are presented. Temperatures on the inner and outer surfaces of the tubes and average tube wall temperatures were determined. The distributions of temperature, circumferential thermal and pressure stresses on the thickness of the tube walls were also calculated.

The general method proposed in the paper can be applied to the design and performance calculations of supercritical steam superheaters.